Acrylic coatings are water-based and generally sold in white, tan, and gray. They also come in different colors. This commercial roof coating is suitable for high UV environments where a reflective roof is desired. Companies make acrylic roof coatings with specialized versions that can be applied to specific substrates. If you or someone you know may be in need of a professional acrylic roof coating, be sure to contact Classic Roofing for a free quote today! Continue reading for the pros and cons of choosing to go with an acrylic roof coating.

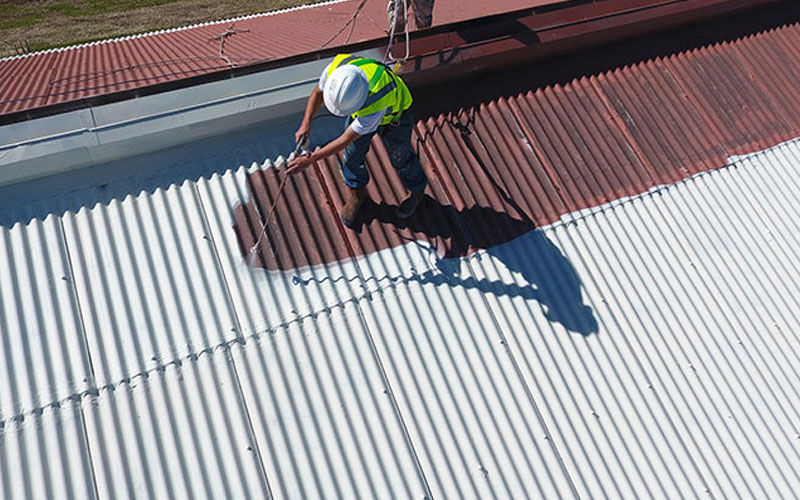

Acrylic roof coatings are generally a popular choice for sloped metal roofs. They are also a serviceable solution for a variety of conventional flat roof substrates including modified bitumen, single-ply, EPDM, built-up roofs, and spray polyurethane foam. Acrylic coating systems are a great solution to restore and protect commercial roofs. There are some important factors to consider when it comes to choosing this particular chemistry. Below, we will explain some of the key strengths and weaknesses of deciding to go with an acrylic roof coating.

Pros of An Acrylic Roof Coating

Cost-Effective:

Compared to other chemistry types, acrylic roof coatings are less expensive and just as durable. This means building owners can expect an acrylic roofing system to deliver long-lasting performance, reduced energy consumption, and decreased maintenance costs. The combination of cost and performance is what makes acrylic coatings such a popular and sensible roof restoration solution.

UV Protection:

Acrylic roof coatings are highly reflective and UV resistant. These important qualities can save money by drastically reducing cooling costs during the hot summer months. Minimizing the sun’s impact on the roof surface not only helps sustain lower energy costs as the system ages but also cools internal building temperatures and extends service life.

Easy Installation:

As a water-based substance, acrylics are easy to work with and install. This means an acrylic roof coating system can be installed in a timely manner without sacrificing quality workmanship and with minimal disruption to day-to-day business operations. Also, installation teams will rarely encounter complications with application equipment, making them more productive and efficient.

Cons of an Acrylic Roof Coating

Ponding Water:

Ponding water will negatively impact the performance of an acrylic roof coating. Ideally, these coatings should only be used on sloped metal roofs or roofs with adequate drainage. Installing an acrylic coating on a flat roof can be very problematic if the roof does not drain properly.

Cold Temperature Applications:

Acrylic coatings are a water-based product and are more susceptible to freezing in colder temperatures. At the time of application, the outside temperature must be at least 50°F and rising, for the coating to properly adhere to the roofing substrate. It’s also worth mentioning that the dry time of an acrylic coating will slow down considerably if the temperature falls below 50°F.

Loss of Mil Thickness:

As acrylic roofing systems age, they tend to lose mil thickness as a result of constant weathering and exposure to extreme environmental conditions. Before considering an acrylic product for your roof, ensure that it has undergone proper testing for specific roofing environments and applications.

After learning about the advantages and disadvantages of applying an acrylic coating to your roof, this will hopefully clear up any questions or concerns you may have. If you’ve decided to choose to go ahead with an acrylic roof coating, contact Classic Roofing to have the job done quickly and easy for any building owner. Call today!

Have questions? Call Classic Roofing & Gutters at 770-424-2010

or email us at [email protected]

Acrylic Roof Coating

Classic Roofing & Gutters is proudly powered by WordPress